Working principle of electrophoresis paint automatic adding equipment:

1.Reduce due to human factors caused by forgetting to add, add too much, save the coating film thickness uniform

2. By collecting the current value of the workpiece electrophoresis production process, calculate the electricity consumption, according to the electrophoretic paint components, and the relationship between the workpiece electricity consumption, calculate the actual consumption of electrophoretic paint, set the amount of addition, set the coefficient, when the consumption reached the set amount will start to add, to ensure that the electrophoretic paint composition percentage in the electrophoresis tank remains stable.

3. The equipment adopts the GRACO pneumatic diaphragm paint pump from the United States, which ensures that the pipeline will not be blocked by residue through the automatic backwash, cleaning and air flushing functions driven by the valve. The addition amount is constant through the electronic weighing function method, so as to achieve accurate painting.

Electrophoretic paint automatic adding equipment composition device main features:

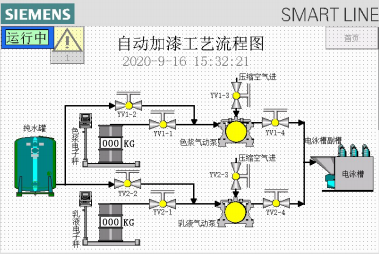

1. The automatic control system collects excess current according to the automatic coulomb calculation of Siemens PLC automatic control center and the automatic communication based on the PLC on the electrophoresis tank rectifier. (Honeywell current mutual inductor can also be used to collect current value and calculate coulomb value through output copper bar of rectifier)

2 . emulsion and color pump using GRACO high performance PTFE pneumatic diaphragm pump, simple and durable without dead point, no air supply lubrication. External directional valve one - time forming structure, strong self - suction. Maximum working pressure (7bar), maximum free flow (3.66M2/h)

3. Shanghai Yaohua XK3190-C8+ instrument is used for electronic weighing. Static weighing system with 4 350Ω sensors is used. With zero clearing, peeling, zero tracking, display gross weight, net weight, tare weight function weighing sensor: high precision, moisture-proof, waterproof, can be installed in the open air. The scale has beautiful appearance, strong structure, innovative high rigidity and high strength design, high strength structure scale body, suitable for all kinds of harsh environment, steel structure, modularization, easy installation.

4. Pneumatic disc valve adopts Beijing Haoli valve industry's pneumatic clamping disc valve, the valve body is made of ultra-light aluminum alloy material, easy to use and install, strong corrosion resistance. The light torque realizes the lightweight and miniaturization of the driving device, the valve plate is spherical, and the long valve neck adopts the vulcanized rubber process.

Valve plate :304SS valve seat: EPDM, valve shaft: 2Cr13, equipped with pneumatic actuator, balanced thrust design: double piston, double spring, variable torque design, at 0° and 90° torque increase, with torque cylinder diameter reduced, reduce gas consumption, faster switching speed, with valve limit switch, intuitive feedback disc valve working condition.

5. Chemical management adopts Formosa UPVC chemical pipe anti-aging, acid and alkali resistance, impact resistance, not easy to deformation, smooth inner wall, not easy to scale, good thermal insulation performance, cold glue combination.

Introduction to man-machine interface:

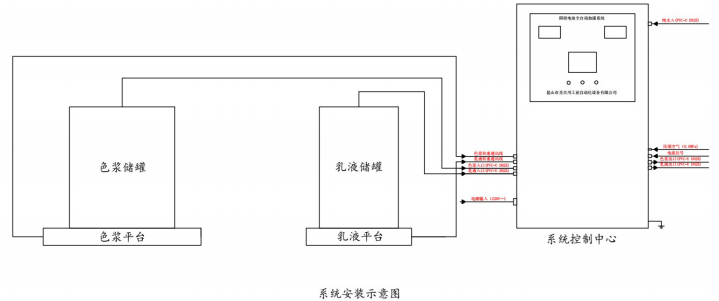

Installation, commissioning, operation management:

1. Our company shall be responsible for equipment installation and adjustment, and submit a complete installation and adjustment result report after adjustment.

2. After the installation is completed, the company will provide a technical engineer to assist your customer in training the operator and smooth operation. According to the functions delivered by your company to be completed, test with your company personnel one by one.

After-sales service and guarantee:

1. Shelf life

1-1. The shelf life of the complete set of equipment is 12 months (counted after equipment acceptance). If the equipment is damaged in normal use within the shelf life, the supplier is responsible for free maintenance. (If the service scope is beyond Jiangsu, Zhejiang and Shanghai, the bus fare and accommodation fee will be charged).

1-2. After the shelf life, the supplier will charge a certain cost of labor and replacement of parts.

Equipment display:

Tag of this article:

About

Company PartnerProduct

Automatic barrel plating production line Fully automatic vertical lifting production line Automatic oxidation production line Waste gas and wastewater treatment equipment Surface treatment auxiliary equipmentNews

Company news Industry Information common problemConatct

Conatct Online messageCopyright © 2021 Suzhou Heyi Environmental Protection Technology Co., Ltd. All Rights Reserved